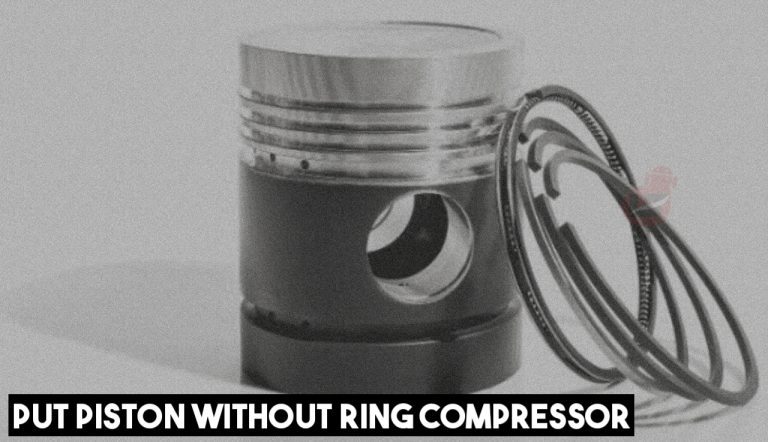

Installing a piston into a cylinder without a ring compressor can be challenging, but it is possible with the right tools and techniques.

By default, while coupling an engine, a mechanic must use the ring compressor tool to carefully tighten the pistons into the cylinder; however, times are changing, and you can now put a piston into a cylinder without a ring compressor tool.

The mechanism doesn’t like using a ring compressor tool because part of it sticks out, making it hard to hit the piston into the cylinder, too thin, or probably because of finance.

Most people use a large hose clamp or their finger for the installation as a substitute, but I’ll show you how to build a shorter piston ring compressor that works perfectly.

However, this DIY tutorial is technical and needs you to do your best to avoid damaging your cylinder or piston; I’ll attach a video for better understanding.

For this tutorial, you’ll need to get a sheet metal, a plier, a tape rule/ruler, a marker, a hammer, and a tool for cutting metal (You can purchase the Tooleague tin snip set for cutting metal sheets on Amazon).

Recommended Tools

- A SHEET METAL

- A PLIER

- A TAPE RULE

- A MARKER

- A METAL CUTTER

- PISTON RING

- PLIERS

- A HAMMER

Once you’ve got the tools ready, let’s delve into building our custom piston ring compressor.

How to Manufacture a Simple Piston Ring Compressor

Once you’ve got the above tools ready, continue with the below steps to manufacture a simple piston ring compressor for your cylinder.

- Take a piece of sheet metal, measure 1 inch wide from the sheet metal (or any width considered fit by you), and cut off excesses using the metal cutter.

- Use tape to circle the head of the piston ring to determine how wide and long the metal sheet should be, take your marking, and cut off the excess metal.

- Now, bend both ends of the metal sheet carefully using a plier (and a hammer if necessary). This creates a point where the plier can grip the piston during installation.

Viola. You’ve got your simple piston ring compressor. Let’slet’show to put a piston in a cylinder using the customized ring compressor.

How to Put a Piston in a Cylinder Without a Ring Compressor

Now, to put a piston into a cylinder, you’re assembling with the new tool, you’ll have to follow the steps below holistically.

- First, lubricate the piston and rings with engine oil to reduce friction and prevent damage to the piston and rings during installation.

- Next, carefully place the piston into the open end of the cylinder and push it down a little to fit.

- Now, get the new piston installation tool and place it on the piston, ensuring it is seated correctly on the device (You can hold the plier if you want the compressor to keep the piston more firmly.)

- Carefully push the piston into the cylinder, using a hammer or other tool to gently tap the installation tool and piston into place. Be careful not to damage the piston or rings during this process.

- Once the piston is fully seated in the cylinder, remove the tool and insert the rings (one at a time) into the grooves of the piston.

- Reinstate the homemade compression tool and hammer the piston into the cylinder.

- Check that the rings are seated correctly in the grooves. If the rings are not installed properly, you may need a ring compressor to position them correctly.

That’That’syou need to know about inserting a piston into a cylinder without a ring compressor.

FAQs

How do I manually put piston rings?

To manually put piston rings, you need to locate the grooves in the piston where the rings go (usually at the top). Once you have found the tracks, carefully slide the curls into place, ensuring they are correctly seated in the grooves.

You may need to use a small tool, such as a ring expander or piston ring pliers, to help you install the rings. After the rings are in place, you can use your fingers or a small tool to open them and ensure they are seated correctly.

How do you compress a piston ring?

You must use a piston ring compressor tool to compress a piston ring. This tool consists of a band or clamp that fits around the outside of the piston and a screw or other mechanism that allows you to tighten the band and compress the rings.

To use the tool, you must carefully fit it around the outside of the piston, ensuring that the rings are correctly aligned with the grooves in the piston. Once the device is in place, you can tighten the screw or other mechanism to compress the rings and allow the piston to be fully seated in the cylinder.

What happens if the piston rings don’tdon’t?

If piston rings do not seat properly, it can lead to several problems, including reduced engine performance and increased fuel consumption. In severe cases, it can even cause the engine to fail.

When piston rings do not seat properly, it can cause leaks in the engine, allowing air and fuel to escape from the combustion chamber.

This can cause the engine to misfire, resulting in a loss of power and reduced fuel efficiency. In addition, the engine may produce more smoke, harming the environment.

What happens if the piston rings are too big?

If piston rings are too big, it can cause several problems, including reduced engine performance and increased fuel consumption. In addition, the rings may not correctly seal the combustion chamber, which can cause the engine to misfire and produce more smoke.

When piston rings are too big, they may not be able to properly expand and contract as the piston moves up and down in the cylinder.

This can cause the rings to become stuck in the grooves in the piston, which can lead to the rings becoming damaged or broken.

In severe cases, the rings may even become stuck in the cylinder, which can cause the engine to seize. To prevent these problems, ensure that the piston rings are the correct size for the engine.

Can you hand-file piston rings?

It is not recommended to hand-file piston rings. Piston rings are precision parts designed to fit particular dimensions, and hand-filing them can cause the rings to lose their proper shape and dimensions.

This can result in the rings not being able to properly seal the combustion chamber, which can cause several problems, including reduced engine performance and increased fuel consumption.

In addition, hand-filing piston rings can be difficult and time-consuming, and it is not a reliable way to ensure that the rings are correctly sized and shaped.

It is best to use a specialized tool, such as a ring filer or grinder, to properly size and shape the rings.

Conclusion

Installing a piston into a cylinder without a ring compressor can be done with the right tools and techniques.

Following the above steps, you can successfully build a simple piston ring compressor that’ll help you to install a piston into a cylinder without a ring compressor.

As an Amazon Service LLC Program Associate, V. Auto Basics earns from qualifying purchases. See Our Affiliate disclaimer.